1: Characteristics of powder metallurgy processing technology

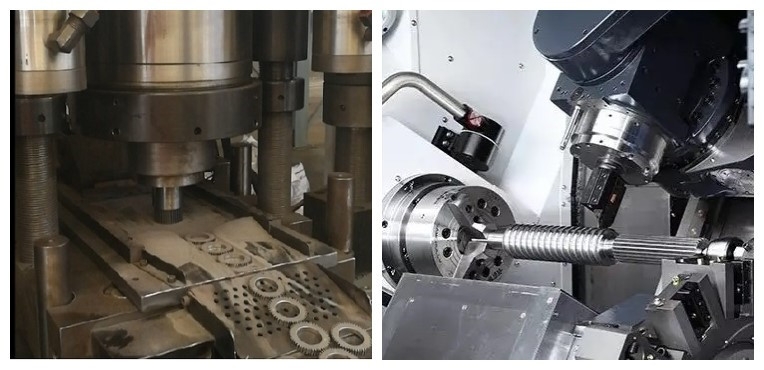

The precision parts produced by powder metallurgy processing have better physical and mechanical properties, and have less material waste, efficient and clean processing, and lower production costs. It can also process complex parts in batches, reducing cutting and other characteristics in major industries. is very widely used.

Two: the characteristics of cutting technology

The size, scope and material of the cutting parts need to be larger, and the cutting production efficiency is high. There are hardness requirements for the cutting materials, and high machining accuracy and low surface roughness can be obtained. However, it is more troublesome to clean the chips during cutting, and it is time-consuming for mass production.

Through the introduction of the advantages of the above two processing technologies, I believe that everyone has the answer in their hearts. Which processing technology is better, powder metallurgy or cutting? The answer must be powder metallurgy processing technology, which has higher efficiency, higher precision, can be mass-produced, and can reduce cost and waste. It is very in line with the high requirements of modern society for products. Society and technology are improving at the same time, we should choose Better processing and forming technology.

Post time: Sep-16-2022