News

-

Chinese traditional festival Spring Festival

The Spring Festival originated from the activities of worshiping gods and ancestors at the beginning and end of the year in ancient times. It has a history of more than 4,000 years. In ancient times, people held sacrificial activities at the beginning of the new year after the end of the one-yea...Read more -

The difference between iron-based and copper-based powder metallurgy parts

Powder metallurgy structural materials are divided into iron-based and copper-based materials according to different base metals. Iron-based materials are divided into sintered iron, sintered low-carbon steel, sintered medium-carbon steel and sintered high-carbon steel according to the amount of ...Read more -

How to judge whether a part is suitable for powder metallurgy production?

Compared with parts produced by other processes, the cost saving advantages of powder metallurgy parts in the case of mass production are very obvious. However, not all powder metallurgy parts have this advantage. So what needs to be considered in the design of powder metallurgy parts? The issues...Read more -

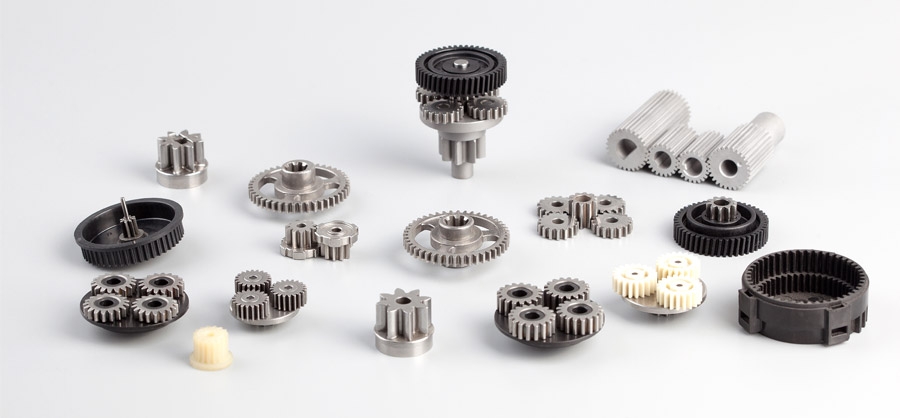

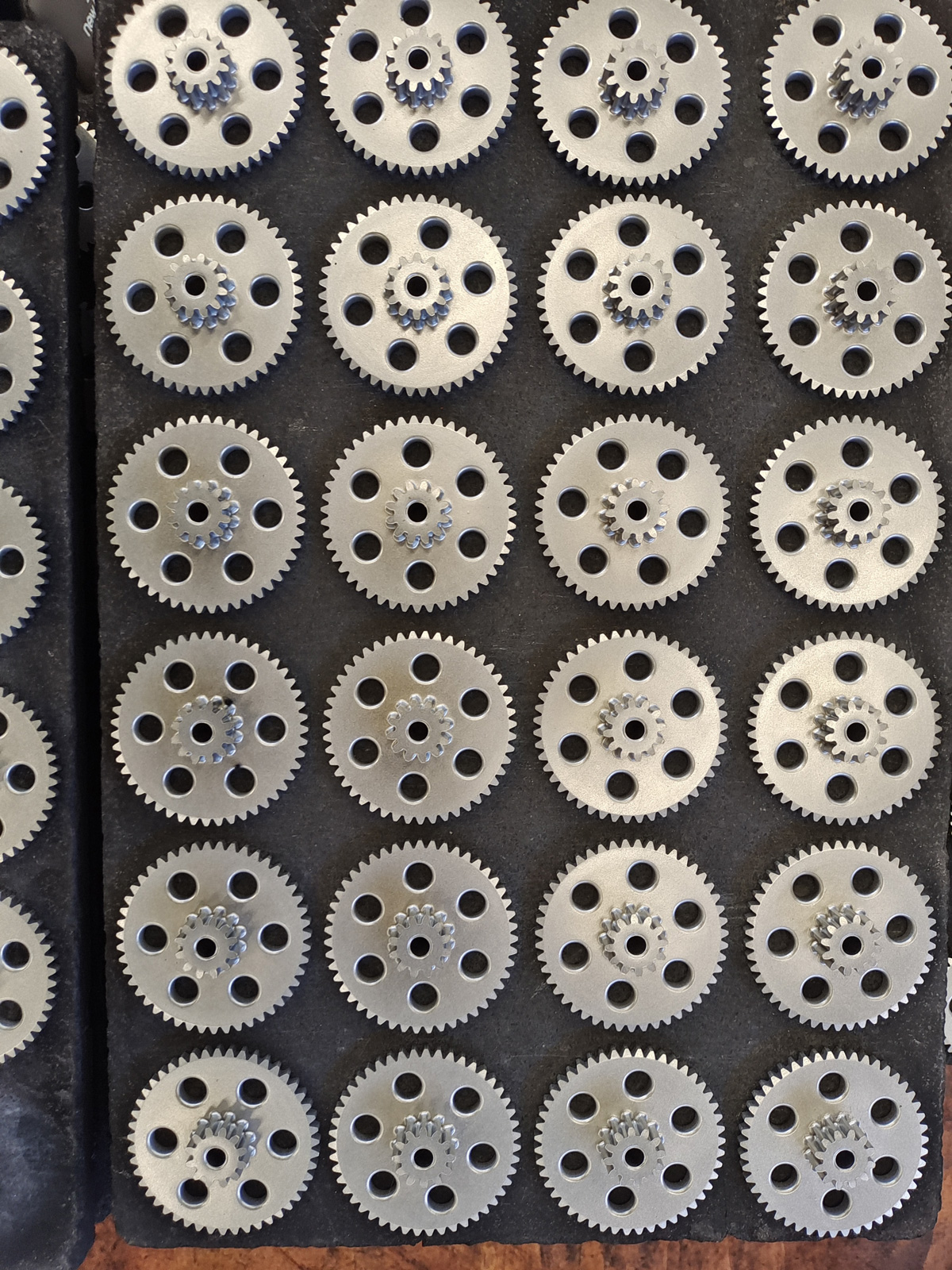

Selection and treatment of powder metallurgy gear materials

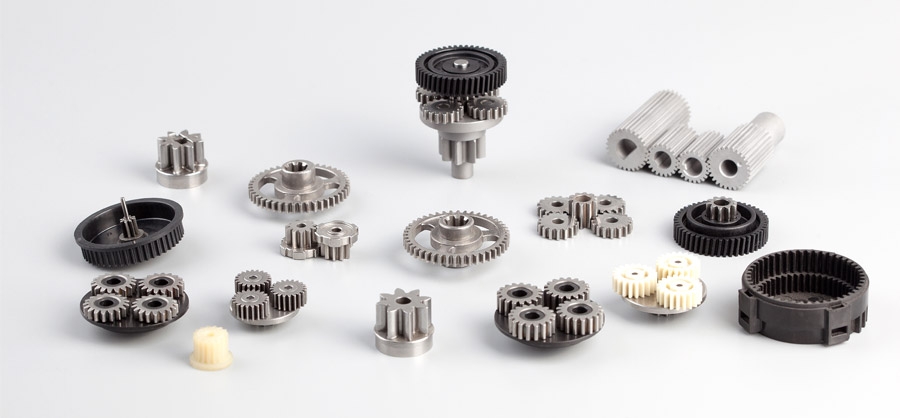

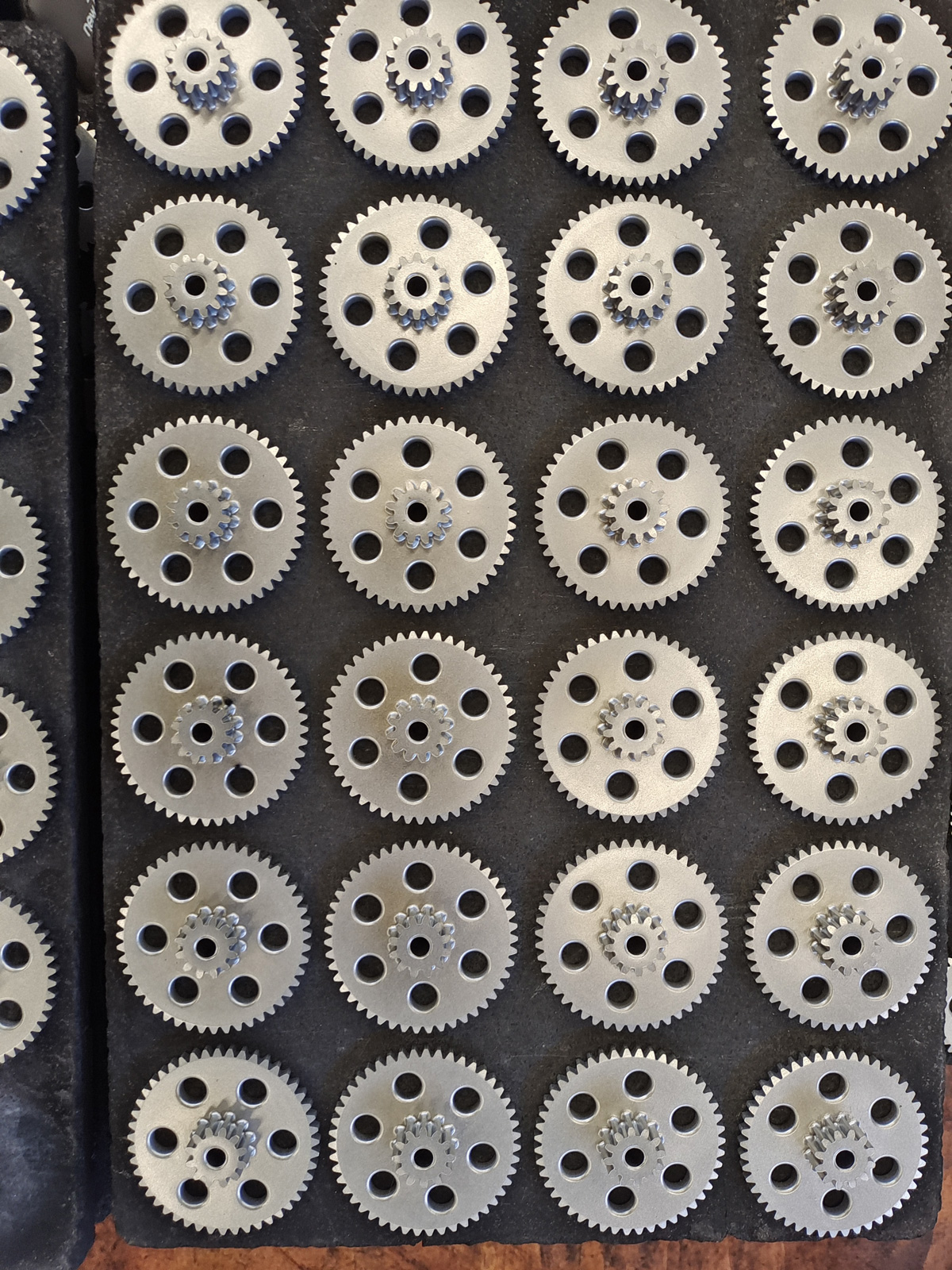

There are many types of gears in production, including sun gear, straight gear, double gear, internal gear, external gear, and bevel gear. The production of powder metallurgy gears must first confirm the materials. There are many medium standards for powder metallurgy materials. As Japan, the Uni...Read more -

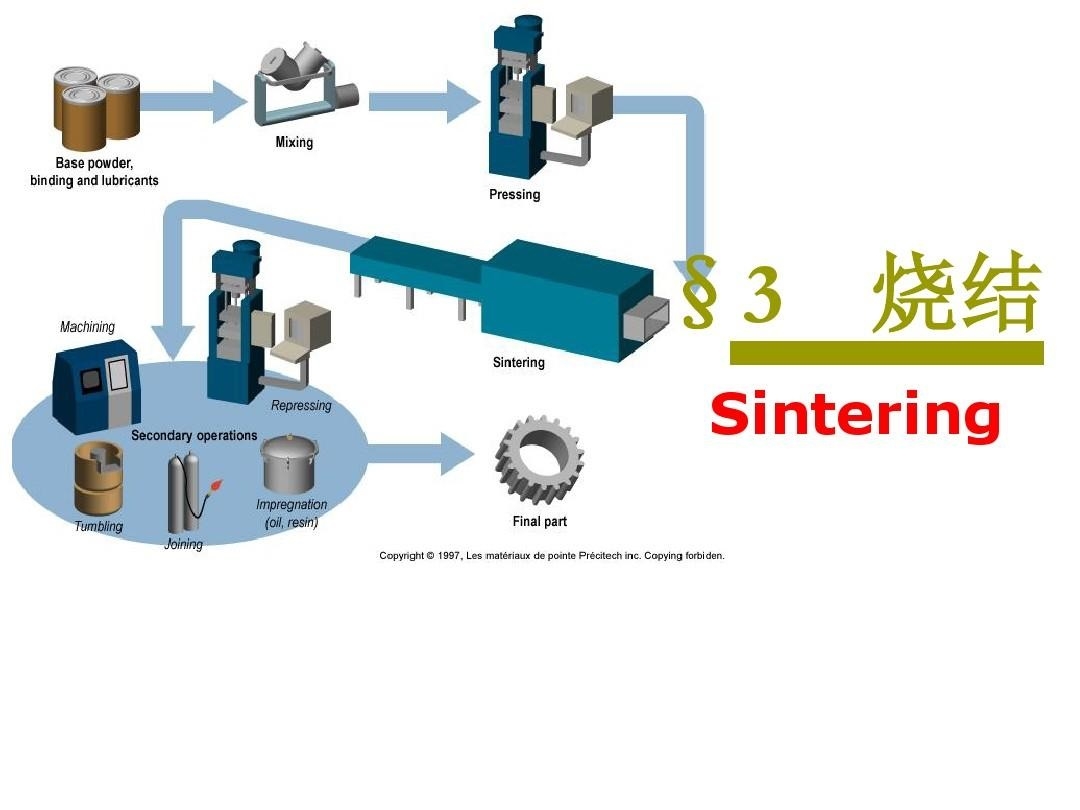

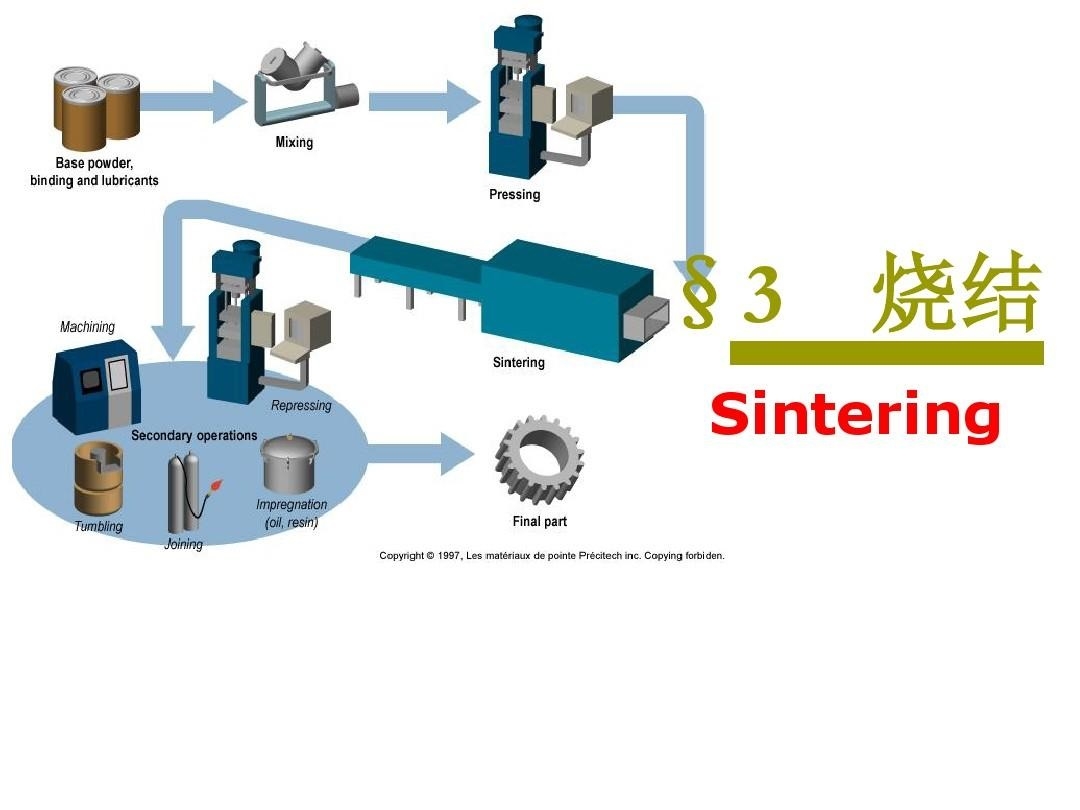

What is the basic process flow of powder metallurgy?

1. Preparation of raw material powder. The existing milling methods can be roughly divided into two categories: mechanical methods and physical chemical methods. The mechanical method can be divided into: mechanical crushing and atomization; Physicochemical methods are further divided into: elec...Read more -

Material cost advantages of powder metallurgy gears

1. The vast majority of refractory metals and their compounds, pseudo alloys, and porous materials can only be manufactured by powder metallurgy. 2. Because powder metallurgy can press the final size of the blank without requiring or rarely requiring subsequent machining, it can greatly save meta...Read more -

Process advantages of powder metallurgy gears?

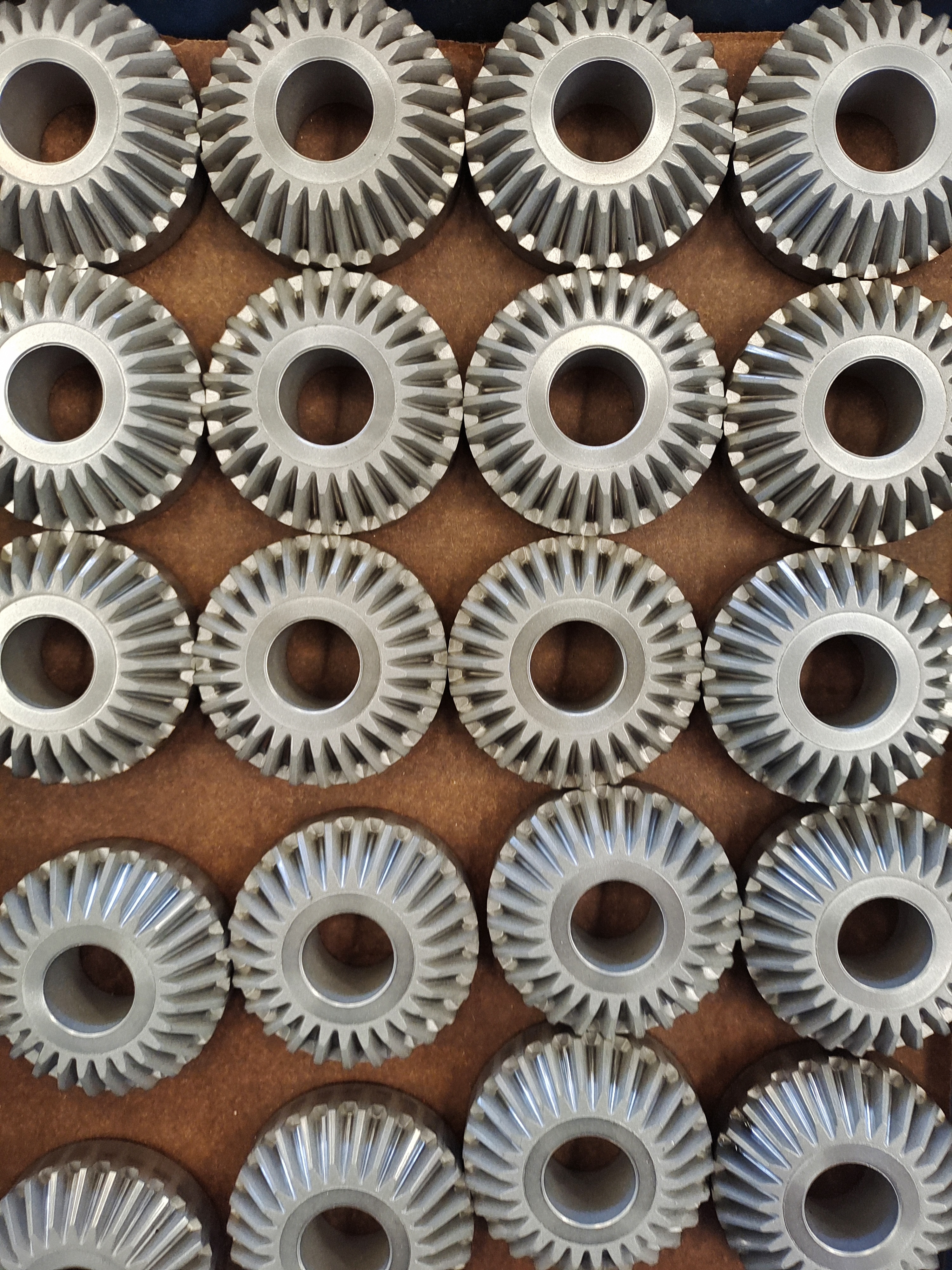

The powder metallurgy process can now produce many types of gears: spur gears, helical gears, double gears, belt pulleys, bevel gears, face gears, straight bevel gears, spiral bevel gears and hypoid gears. Users usually choose powder metallurgy to manufacture gears because of its multiple technol...Read more -

Technical characteristics of powder metallurgy

◆ Material saving, high material utilization rate; ◆ Energy saving, low production energy consumption; ◆ Suitable for mass production, the larger the output, the lower the production cost; ◆ Suitable material composition can be formulated according to the use function of the part; ◆ Complex shape...Read more -

How to prevent rust of powder metallurgy gears

Anti-rust oil protect the Powder metallurgy gear from rust After the production of powder metallurgy gears is completed, in order to prevent the gears from rusting during storage and transportation, a certain amount of powder metallurgy anti-rust oil is usually sprayed on the surface before packi...Read more -

What are the main applications of powder metallurgy gears?

1. Automobile engine: Camshaft, crankshaft timing pulley, water pump, oil pump pulley, main and driven gears, main and driven sprockets, cams, bearing caps, rocker arms, bushes, thrust plates, valve guides, intake and exhaust valve seats, Car gearbox 2. Various high and low speed synchronizer gea...Read more -

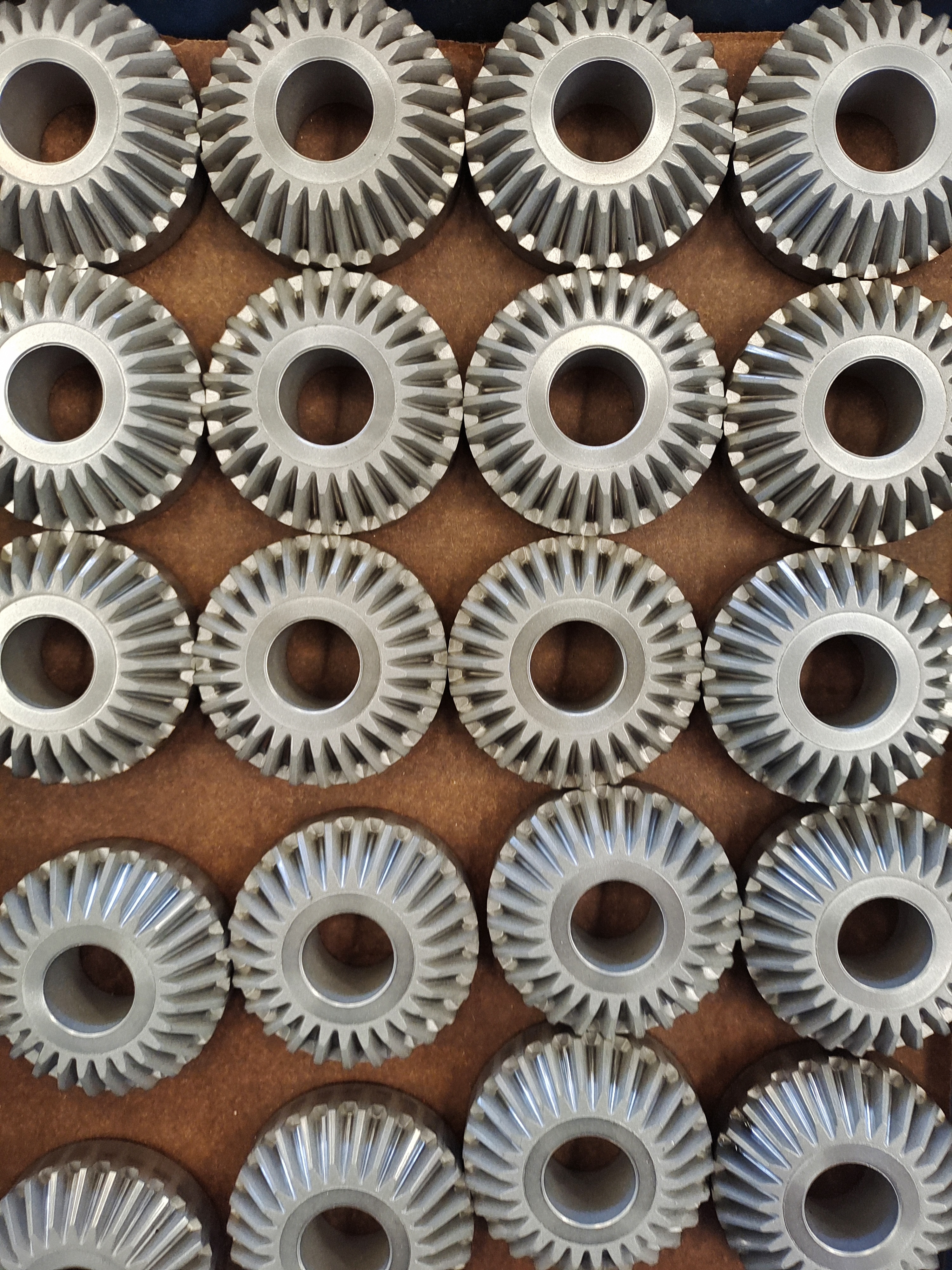

The characteristics of various bevel teeth

1. Straight bevel gear is the most basic bevel gear. The processing is simple, but the transmission accuracy is too poor, and the instantaneous transmission ratio is not accurate. It is only transmitted as a general change of direction, and the speed and transmission ratio requirements are not st...Read more -

Powder Metallurgy sintering process

Powder metallurgy sintering hardening is a process that combines sintering and heat treatment, that is, after a certain material is sintered and rapidly cooled, martensite (usually >50%) is generated in the metallographic structure, so that the material is in production Play a more effective r...Read more -

Powder metallurgy mechanical parts

Powder metallurgy iron-based structural parts are structural parts manufactured by powder metallurgy technology with iron powder or alloy steel powder as the main raw material. The requirements for this kind of parts are to have sufficiently good mechanical properties, wear resistance, good machi...Read more -

What kind of processing method is powder metallurgy?

Powder metallurgy is a process technology that produces metal or uses metal powder as raw materials, after forming and sintering, to produce metal materials, composites and various types of products. Powder metallurgy technology process 1. Powder preparation and compression molding Commonly used...Read more -

Gear surface treatment shots blasting

Gears surface after the shots blasting process will have better finish and also higher mechanical characters. Shot blasting process is an important method to improve the bending fatigue strength and contact fatigue strength of gear teeth, and it is an important way to improve gear anti-seizure ab...Read more