News

-

Powder Metallurgy type: MIM and PM

What is powder metallurgy technology ? Powder metallurgy technology was first used in the United States in 1870. It used a metal powder as a raw material, and then pressed copper-lead alloy bearings to realize the self-lubricating technology of the bearing, and produced various parts and componen...Read more -

Gear for motor

Powder metallurgy gears with excellent fatigue performance and dimensional accuracy to meet the stringent requirements of the motor manufacturing industry. Customized metal gear processing, low noise, super wear resistance, high precision and high density occupy a place in the motor industry gear...Read more -

Traditional powder metallurgy iron-based parts-gears

In many cases, powder metallurgy gears have low requirements for mechanical properties and high dimensional accuracy. Generally, the density is 6.9~7.1. The forming process is not high. The sintering process is high. To prevent sintering deformation, Cu can be added. Anti-sintering shrinkage. Wit...Read more -

Why choose the powder metallurgy gear for Motor ?

Powder metallurgy technology manufactures gears with excellent fatigue performance and dimensional accuracy to meet the stringent requirements of the motor manufacturing industry. Customized powder metallurgy gear processing, low noise, super wear resistance, high precision and high density occup...Read more -

Powder metallurgy stainless steel

Stainless steel sintered parts is stainless steel manufactured by powder metallurgy. It is a powder metallurgy material that can be made into steel or parts. Its advantages are to reduce the segregation of alloying elements, refine the microstructure, improve performance, save raw materials, save...Read more -

Powder metallurgy parts used in Automobile

Powder metallurgy is a material-saving, energy-saving, and labor-saving manufacturing technology for mechanical structural parts that can manufacture complex-shaped parts. Powder metallurgy has superior performance and relatively low cost, which is very suitable for mass production. Therefore, po...Read more -

Powder metallurgy bushing and sintered sleeve

The service life of self-lubricating powder metallurgy bushings is usually determined by the amount of lubrication in the suction pores. Powder metallurgy technology is currently one of the methods that can reduce the waste of raw materials as much as possible, according to the high-precision lev...Read more -

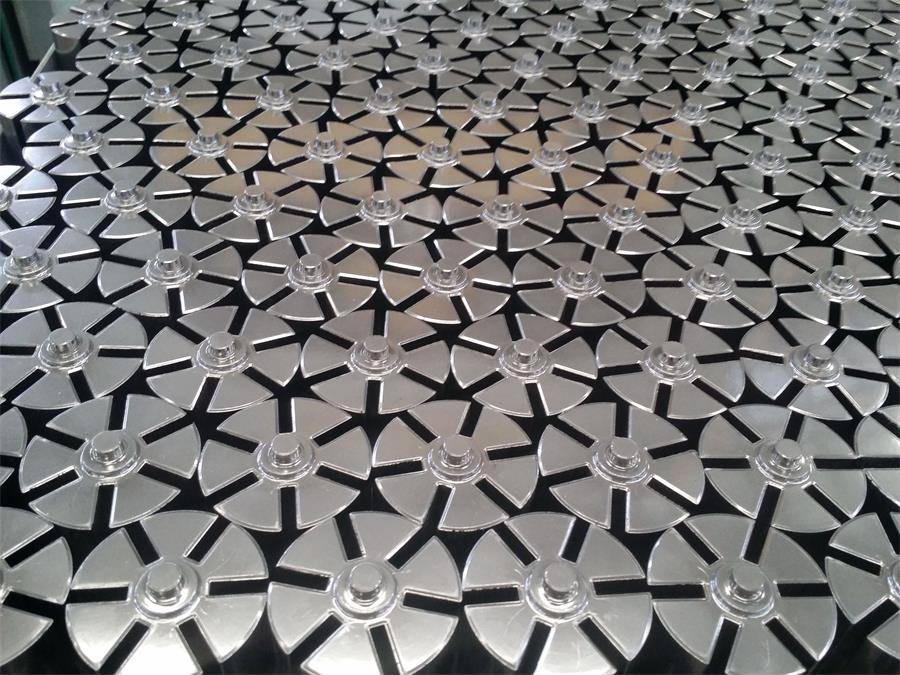

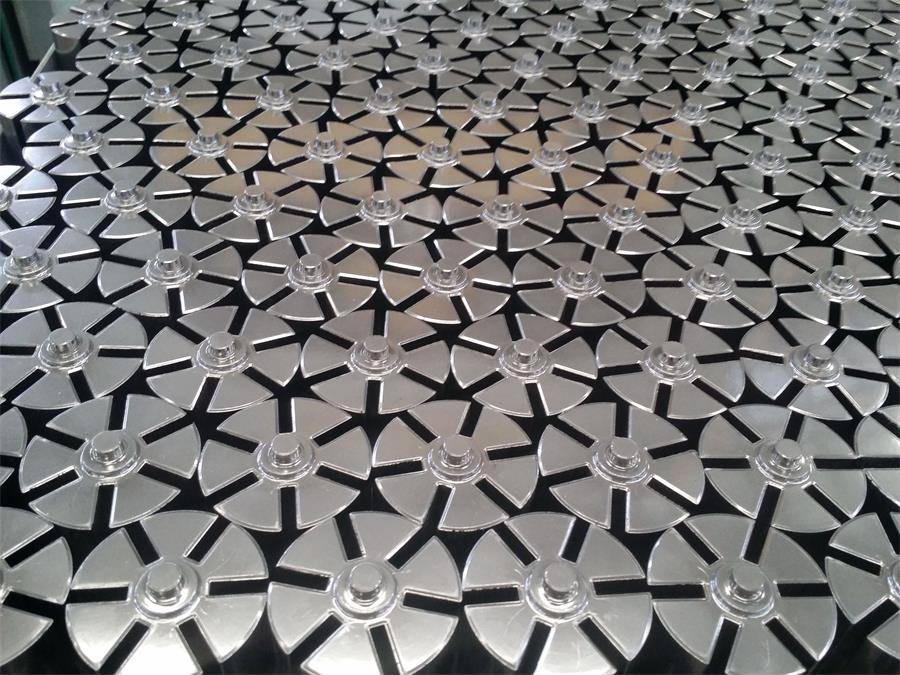

Powder metallurgy gear

Gear is a kind of very precise spare parts. The traditional process is difficult to process, complicated to process, cumbersome to process, high in processing cost, and cannot be mass-produced. At present, powder metallurgy processing technology can solve these problems well. Processing technolog...Read more -

OEM GEAR FOR SMALL MICRO MOTOR

Factory OEM the micro gear, double gear for the LG Refrigerator ice breaker.This series gears are already get through the samples testing All these gears are assembly together as gearbox for the motor. All the technical requests are strictly achieve the customer’s standard. Gears for gearbox are ...Read more -

Timing tensioner

Powder metallurgy parts are widely used in automobile engines. The powder metallurgy pulley and other accessories form an idler pulley, plus a fixed shell, tension arm, torsion spring, rolling bearing and spring sleeve to form a tensioner , which can automatically adjust the tension according to ...Read more -

The advantages and disadvantages of powder metal and forgings Ⅱ

B. Forged metal parts 1. Advantages of forging: Change the particle flow of the material so that it flows in the shape of the part. Create parts that are stronger than other manufacturing processes. Forged parts are very suitable for use in dangerous or extremely inconvenient situations, such as ...Read more -

The advantages and disadvantages of powder metal and forgings Ⅰ

For a long time, engineers and potential buyers have been comparing powder metallurgy with competing processes. As for powder metal parts and forged parts, like any other comparison of manufacturing methods, it helps to understand the advantages and potential disadvantages of each process. Powder...Read more -

Surface treatment for powder metallurgy parts

The main purpose of surface treatment of powder metallurgy parts: 1. Improve wear resistance 2. Improve corrosion resistance 3. Improve fatigue strength The surface treatment methods applied to powder metallurgy parts can basically be divided into the following five categories: 1. Coating: Co...Read more -

Advantages and Contrast

P/M offers designers and users a versatile and efficient method of producing parts and components. The process is versatile because it is applicable for simple as well as complex shapes, and a full range of chemical, physical and mechanical properties are achievable. The process is efficient beca...Read more -

Powdered Metal Gears

Powdered metal gears are made through the process of powder metallurgy. There have been many advances to this process over the years, which have in turn caused an increase in the popularity of powdered metal as a gear material. Powdered metal gears are used in many industries, but are used most i...Read more