News

-

what factors affect the quality of powder metallurgy pressing forming of automobile parts

Powder metallurgy is a new type of net near-molding technology, which uses melting, heating, injection and pressing of metal powder to carry out the required mold molding. For some special materials such as refractory metals, refractory metals, high alloy and so on. So what factors affect the qua...Read more -

Five incorrect operations of diesel generator sets

1. The diesel engine runs when the engine oil is insufficient At this time, due to insufficient oil supply, the oil supply to the surfaces of each friction pair will be insufficient, resulting in abnormal wear or burns. 2. Shut down suddenly with load or stop immediately after unloading the load ...Read more -

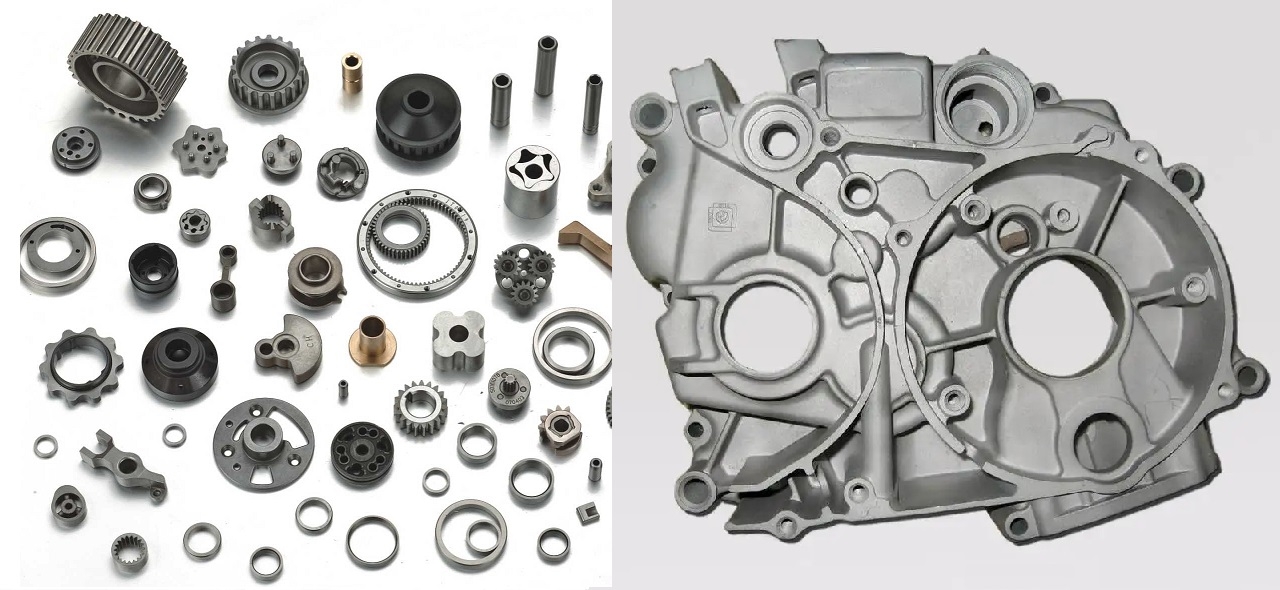

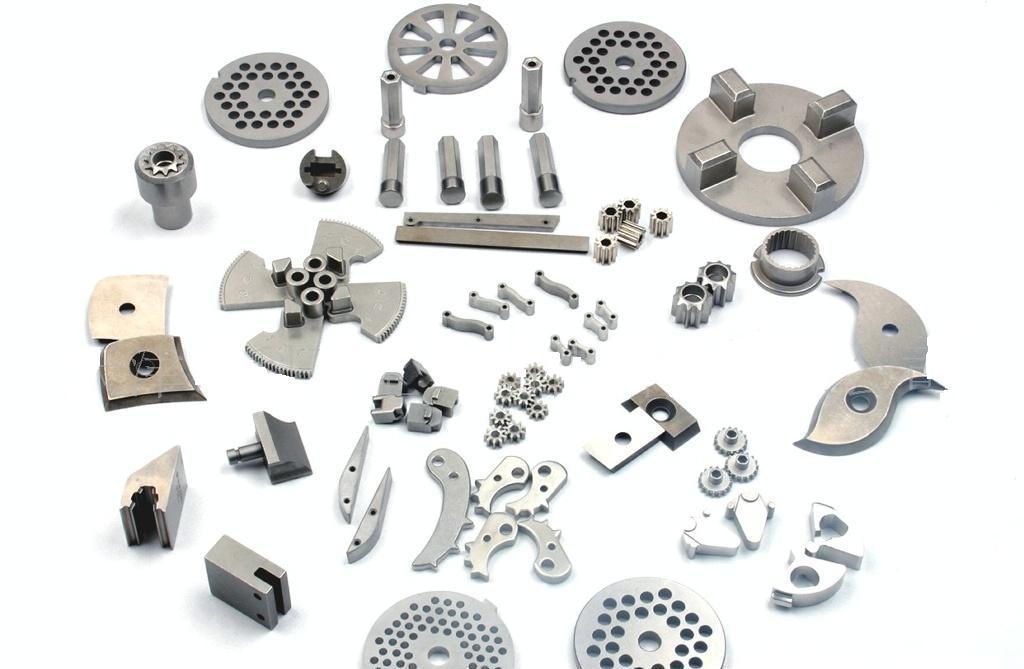

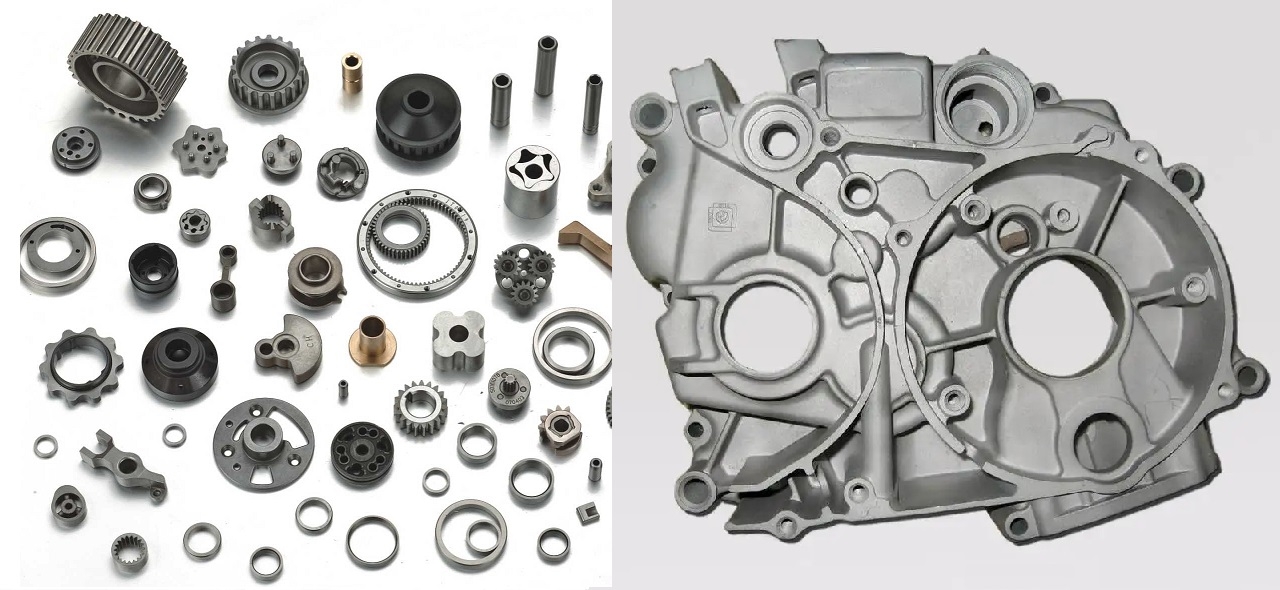

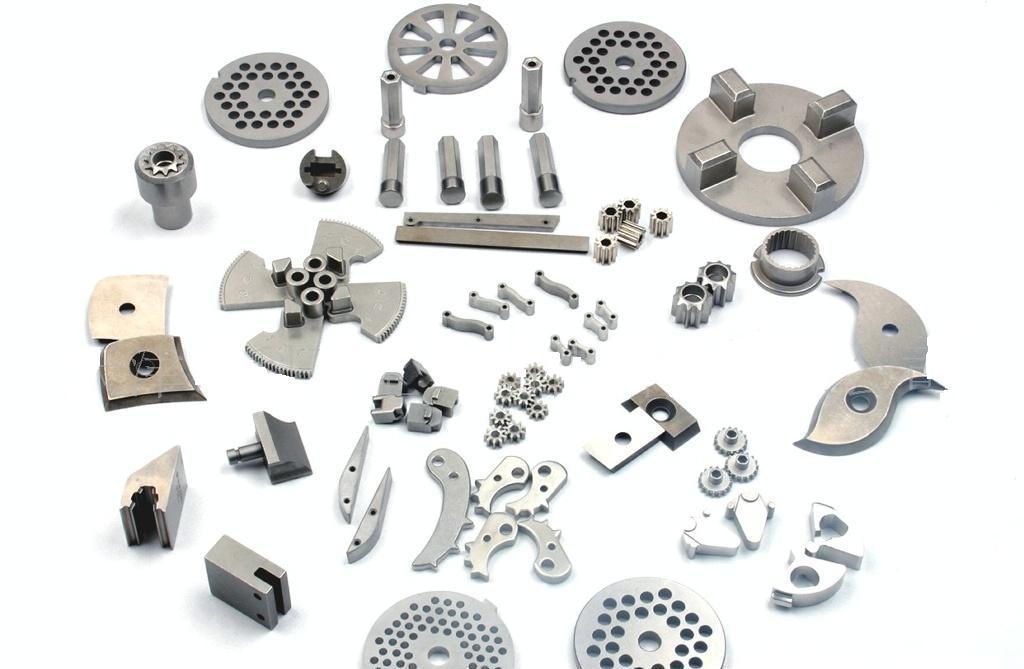

Powder metallurgy gear

Powder metallurgy gear parts are the most widely produced parts in powder metallurgy industry. Powder metallurgy gear is the product of one-time net compression molding technology with less machining and inorganic processing. It is difficult to count powder metallurgy gear separately in the whol...Read more -

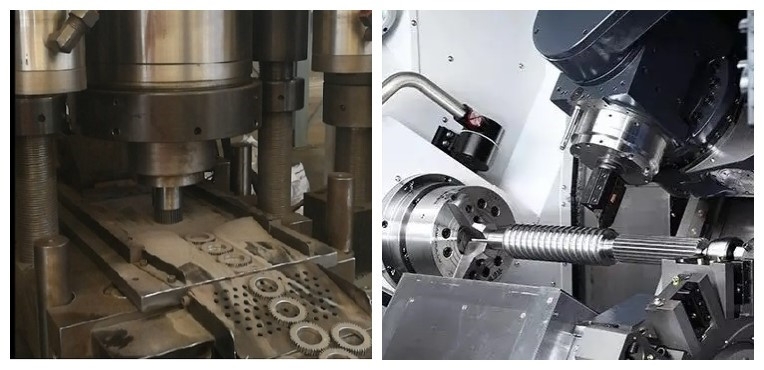

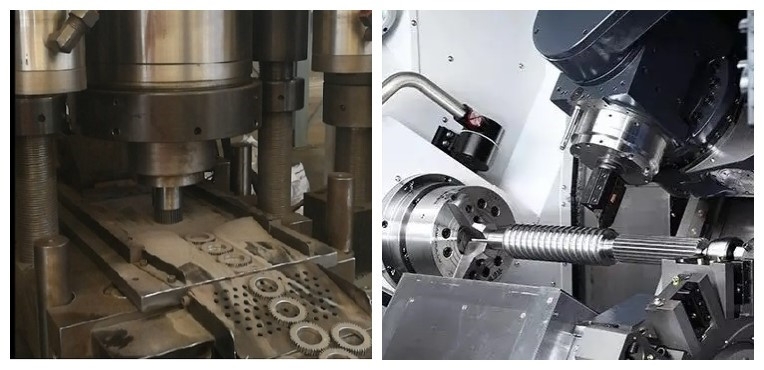

Four pressing steps in powder metallurgy

Compaction is an important production process in the production of powder metallurgy parts. The pressing process of powder metallurgy is divided into four steps. First, the preparation of powder involves the preparation of materials. According to the material requirements, the ingredients are pre...Read more -

The difference between PM powder metallurgy parts and injection powder metallurgy parts

PM powder suppression technology and injection molding technology belong to special technologies, precise manufacturing, and all have good material processing characteristics 1. Powder metallurgical suppression molding is to rely on gravity to fill the mold with powder and squeeze through the pr...Read more -

Some surface treatment procedures to enhance the performance of powder metallurgy parts

1. Immersion Powder metallurgy components are inherently porous. Impregnation, also known as penetration, involves filling most pores with the following substances: plastic, resins, copper, oil, another material. Placing the porous component under pressure can cause leakage, but if you soak the ...Read more -

Comparison of powder metallurgy parts and ordinary structure parts

Our factory professional in the powder metallurgy parts OEM. As the years production of powder metallurgy gears manufacturer, we supply: sintered components which also called sintered parts, powder metallurgy gear, powdered metal gears, sintered sun gears, sintered gears, sintered metal gear, sin...Read more -

Do you know the surface treatment of these gears?

The surface treatment of the gear is processed to improve the surface state of the material. Generally, there are black treatment (surface oxidation), solid lubrication treatment, galvanizing, phosphorurative treatment, chemical silver plating, and raydent surface treatment. Their own characteris...Read more -

Gear material selection Ⅰ

The range of gear materials can be made from wood to the current synthetic material, including black metals, non -ferrous metals, powder metals and plastic. Ancient gears were found even made of stones. The selected material will affect the carrying capacity, strength, anti -point erosion, life a...Read more -

Comparison of powder metallurgy and Blanking process

The choice between powder metallurgy and blanking generally depends on the complexity of materials and products. If the powder metallurgical material can meet the performance of the parts, a part can be made by a piece of mold by a metal plate which is the blanking process. At the same time, mold...Read more -

Comparison of powder metallurgy and die casting process

The choice between powder metallurgy and die casting is often a question of part size or material requirements rather than economics. Commonly used die casting materials are aluminum alloys, magnesium alloys and zinc alloys, and copper alloy die castings are also used to a limited extent. Due to ...Read more -

Which processing technology is better, powder metallurgy or cutting?

1: Characteristics of powder metallurgy processing technology The precision parts produced by powder metallurgy processing have better physical and mechanical properties, and have less material waste, efficient and clean processing, and lower production costs. It can also process complex parts i...Read more -

Powder metallurgy parts application in the Auto industry

Base on the superior performance and low cost of the powder metallurgy parts, more and more sintered parts are widely and comprehensively used in the auto industry. Among the engine, The car chassis system: shock absorber parts, guides, pistons and low valve seat. Breaking system; ABS sensor,br...Read more -

Powder metallurgy parts

structural parts Structural parts are mainly used to withstand external forces. Specific products mainly include bearings or steel shells. For those who are familiar with mechanical equipment, they all know how important football is to equipment. Bearings not only play a role in lifting, but also...Read more -

Dimension change of powder metallurgy parts during sintering

In production, the dimensional and shape accuracy of powder metallurgy products is very high. Therefore, controlling the density and dimensional changes of the compacts during sintering is an extremely important issue. Factors that affect the density and dimensional changes of sintered parts are:...Read more