News

-

Powder metallurgy bearing also called oil-bearing bearings, what’s the advantages?

Powder metallurgy bearings are made of metal powder and other anti-friction material powders pressed, sintered, shaped and oil-impregnated. They have a porous structure. After being soaked in hot oil, the pores are filled with lubricating oil. The suction effect and frictional heating cause the m...Read more -

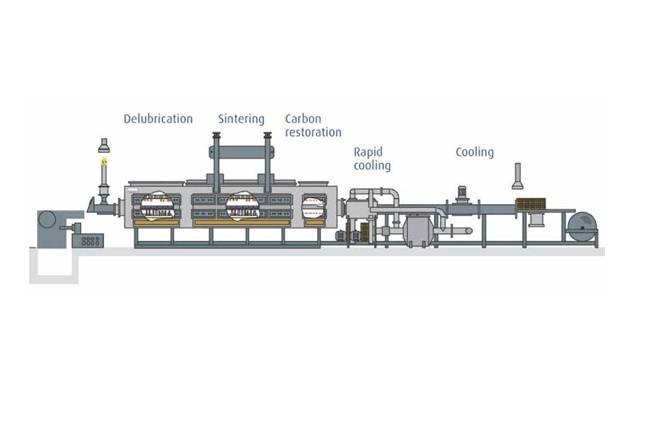

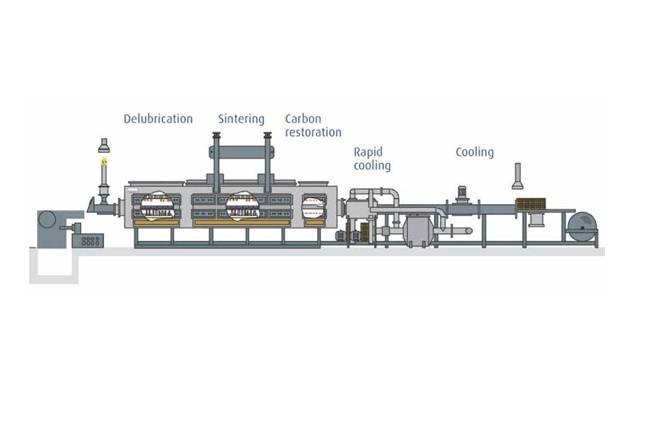

Powder Metallurgy Sintering Process

Sintering is a heat treatment applied to a powder compact in order to impart strength and integrity. The temperature used for sintering is below the melting point of the major constituent of the Powder Metallurgy material. After compaction, neighbouring powder particles are held together by cold ...Read more -

The Impact of the COVID-19 on the Automotive Market

COVID-19’s impact on the automotive supply chain may be substantial. Countries that have been heavily impacted by the outbreak, in particular, China, Japan and South Korea, account for a significant share of global auto manufacturing. China’s Hubei province, the pandemic’s epicenter, is one of th...Read more -

Powder Metallurgy—Intrinsically Sustainable

The Sustainability Role of Powder Metallurgy For many years, powder metallurgy has been delivering sustainable value as an industry. We have just not defined ourselves or compared our products and processes to competing metal-forming process alternatives in those terms. The balance of this discus...Read more -

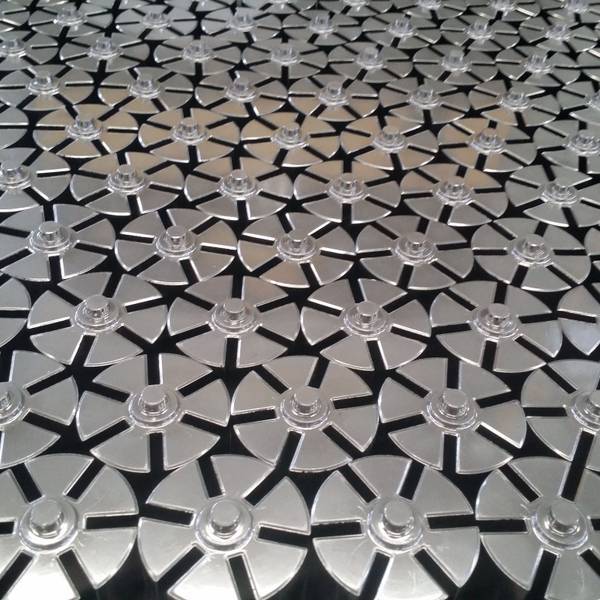

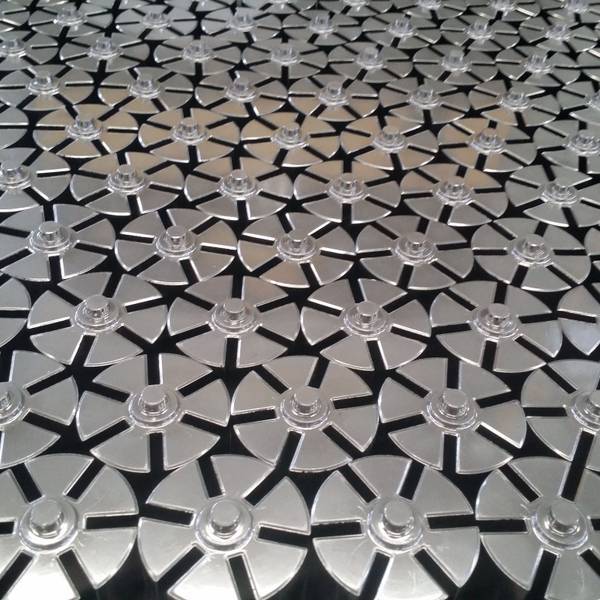

Advantages of Powdered Metal Parts

Flexibility The powdered metal parts process provides unparalleled flexibility in the design of complex net shape or near-net shape parts with unique mechanical properties. Consistency Consistent dimensions from part to part, order to order, year to year. Precision Dimension accuracy is controlle...Read more -

Powder metallurgy parts applications in Aerospace

Aero-engine and land-based gas turbine applications Aero-engine and land-based gas turbine applications for Powder Metallurgy products require extremely good properties and the PM-based process routes in this sector generally incorporate Hot Isostatic Pressing (HIP). For nickel-based superalloy t...Read more -

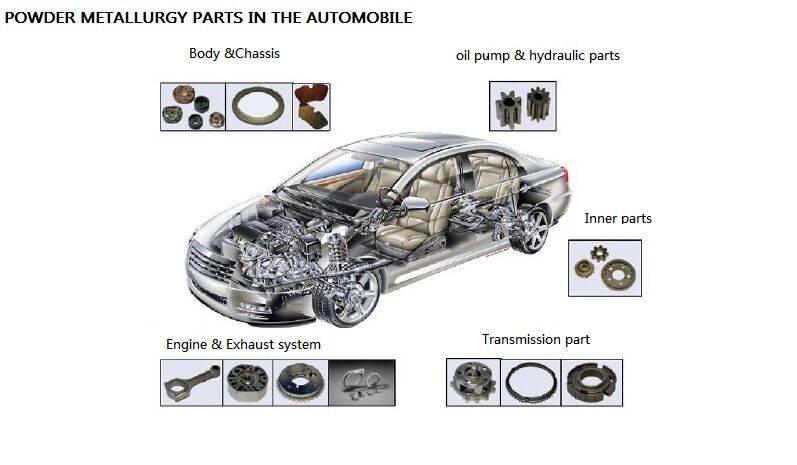

The Powder Metallurgy Components Market around the World

Global Powder Metallurgy Components Market, by Product Ferrous Metals Iron Steel Non-ferrous Metals Aluminum Others (including Copper, Tungsten, and Nickel) Global Powder Metallurgy Components Market, by Application Automotive Transmission Parts Gears Synchronizers Others (including Oil Be...Read more -

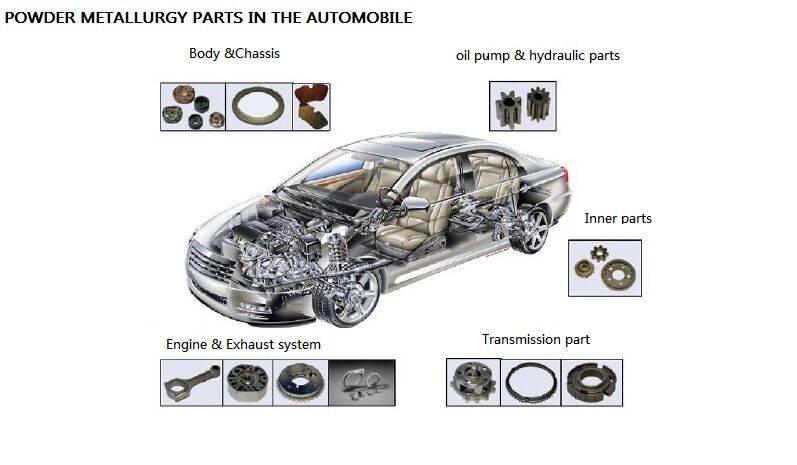

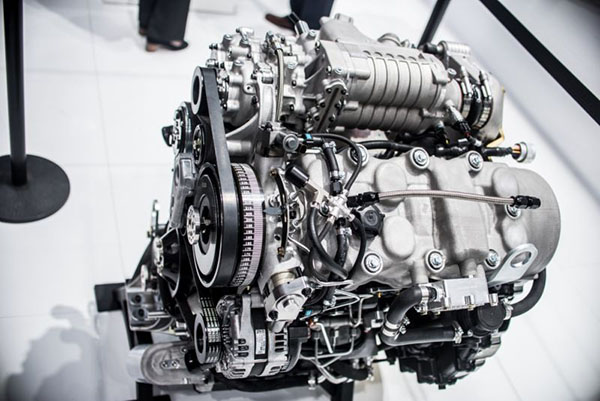

The Value of Powder Metallurgy in the Automotive Market

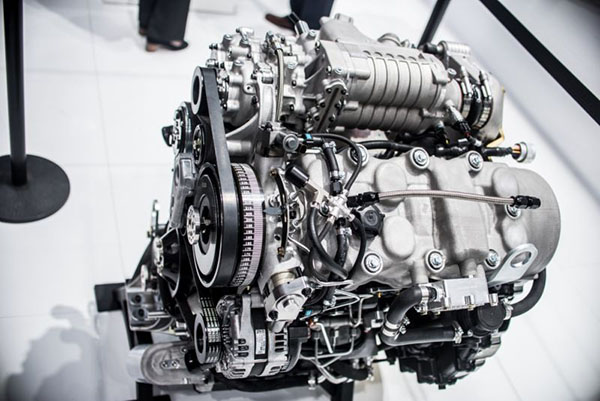

The predominant market for Press/Sinter structural Powder Metallurgy parts is the automotive sector. On average across all geographical regions, around 80% of all Powder Metallurgy structural components are for automotive applications. Around 75% of these automotive applications are components fo...Read more -

Powder metallurgy

Powder metallurgy (PM) is a term covering a wide range of ways in which materials or components are made from metal powders. PM processes can avoid, or greatly reduce, the need to use metal removal processes, thereby drastically reducing yield losses in manufacture and o...Read more -

Rack and pinion for greenhouse ventilation system

OEM PINION ACCORDING TO THE DRAWING Powder metallurgy pinion which install in the ventilation supply the good performance to help your vent roof open and closed. RACK & PINIONS - CUSTOM MADE TO SUIT YOUR REQUIREMENTS Rack & pinions are available in many various configurations. Pinions are...Read more -

What is the purpose of copper infiltration into a PM component, and how is it accomplished?

Components are copper infiltrated for a number of reasons. Some basic desired results are improvements to tensile strength, hardness, impact properties, and ductility. Copper-infiltrated components will also have a higher density. Other reasons customers may elect copper infiltration are for wear...Read more -

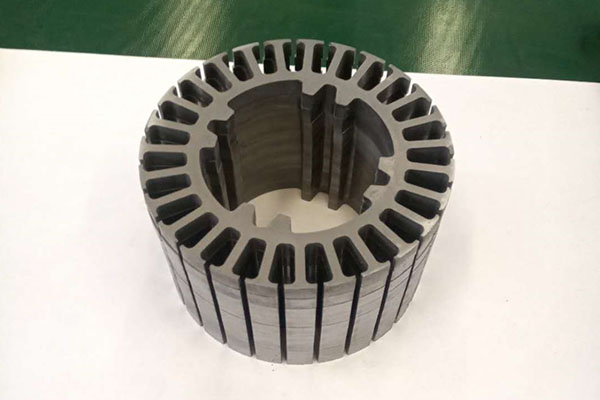

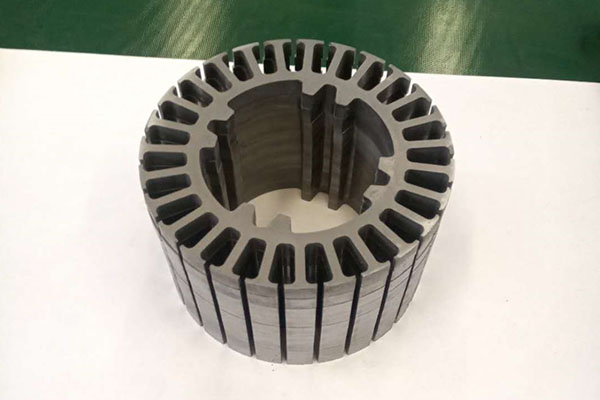

Soft magnetic

In recent decades, trends in automotive and other industries have spiked demand for new magnetic materials. As a result, in the mid-1990s the very first components made from soft magnetic composite were born. And the trend of using these soft magnetic composites (SMCs) only continues to grow. Tho...Read more -

Leave lubrication to the parts themselves

Improper lubrication practices are a good way to ruin a product, machine or process. Many manufacturers realize the dangers of under-lubrication - increased friction and heat, and ultimately, a ruined bearing or joint. But it isn't just a lack of lubrication that can limit an item's effectiveness...Read more -

Modern metal components meet needs of auto manufacturers

Manufacturers of automobiles and precision parts are constantly on the look out for new and more effective materials to enhance the specifications and performance of their products. Car makers are especially interested in using innovative substances in their vehicles, leading them to experiment w...Read more -

When to use powder metallurgr(pm)?

When to use PM is a commonly asked question. As you would expect there is no single answer, but here are some general guidelines. To make a PM part requires tooling. The cost of the tooling depends on the size and complexity of the part, but can range from $4,000.00 to $20,000.00. Production quan...Read more