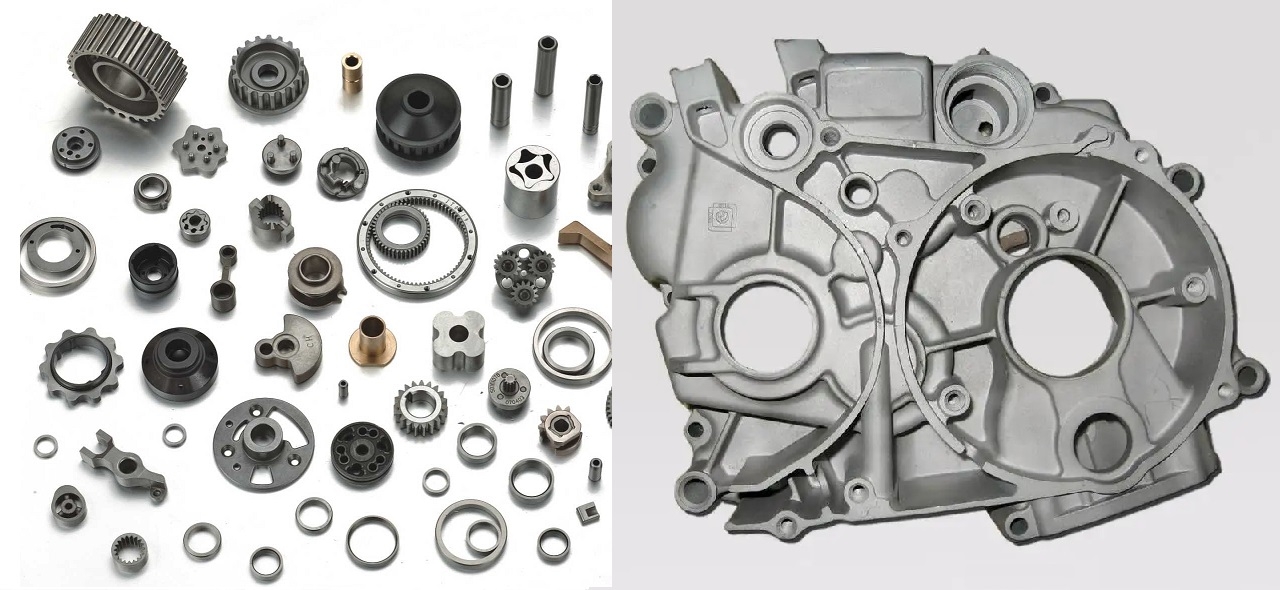

Kev xaiv ntawm hmoov metallurgy thiab tuag casting feem ntau yog ib lo lus nug ntawm qhov loj me lossis cov khoom yuav tsum tau ua ntau dua li kev lag luam.Feem ntau siv cov khoom siv tuag casting yog aluminium alloys, magnesium alloys thiab zinc alloys, thiab tooj liab alloy tuag castings kuj siv rau qhov tsawg.Vim lub siab melting point ntawm ferroalloy thiab stainless hlau, hmoov metallurgy txheej txheem yuav tsum tau siv.

Piv nrog rau cov hmoov hlau metallurgy cov khoom, cov hlau txhaj tshuaj molding qhov chaw, qhov ntev ntawm qhov tuag casting qhov chaw tuaj yeem zoo ib yam lossis ntau dua.Thaum xav tau cov khoom tseem ceeb, nws tsim nyog siv cov txheej txheem hmoov metallurgy.Piv txwv li, 1: lub zog muaj zog heev, lub zog tensile ntawm qee cov hlau-raws li sintered alloys yog ntau tshaj peb zaug siab dua li cov alloys tuag.2: Kev hnav tsis kam thiab kev sib txhuam siab txo kev ua haujlwm, uas tuaj yeem daws tau los ntawm cov hlau-raws li thiab tooj liab-raws li sintered alloys impregnated nrog lubricating roj.3: Kev ua haujlwm siab kub, uas tuaj yeem daws tau los ntawm cov hlau-raws li thiab tooj liab-raws li sintered alloys.4: Corrosion kuj, tooj liab-raws li sintered alloy thiab sintered stainless hlau tuaj yeem ua tau raws li qhov yuav tsum tau ua

Nruab nrab ntawm cov hmoov hlau metallurgy thiab tuag casting, zinc tuag castings yuav yog ib qho kev hloov ntawm cov hlau-raws li hmoov metallurgy cov khoom thaum qhov kev khiav hauj lwm kub tsis siab tshaj 65 ° C thiab nruab nrab lub zog yuav tsum tau.Cov txheej txheem ob yog qhov zoo sib xws ntawm qhov tseeb qhov tseeb thiab qhov xav tau ntawm machining.Tab sis nyob rau hauv cov nqe lus ntawm cov cuab yeej thiab machining nqi, hmoov metallurgy feem ntau muaj txiaj ntsig zoo dua.

Post lub sij hawm: Sep-26-2022