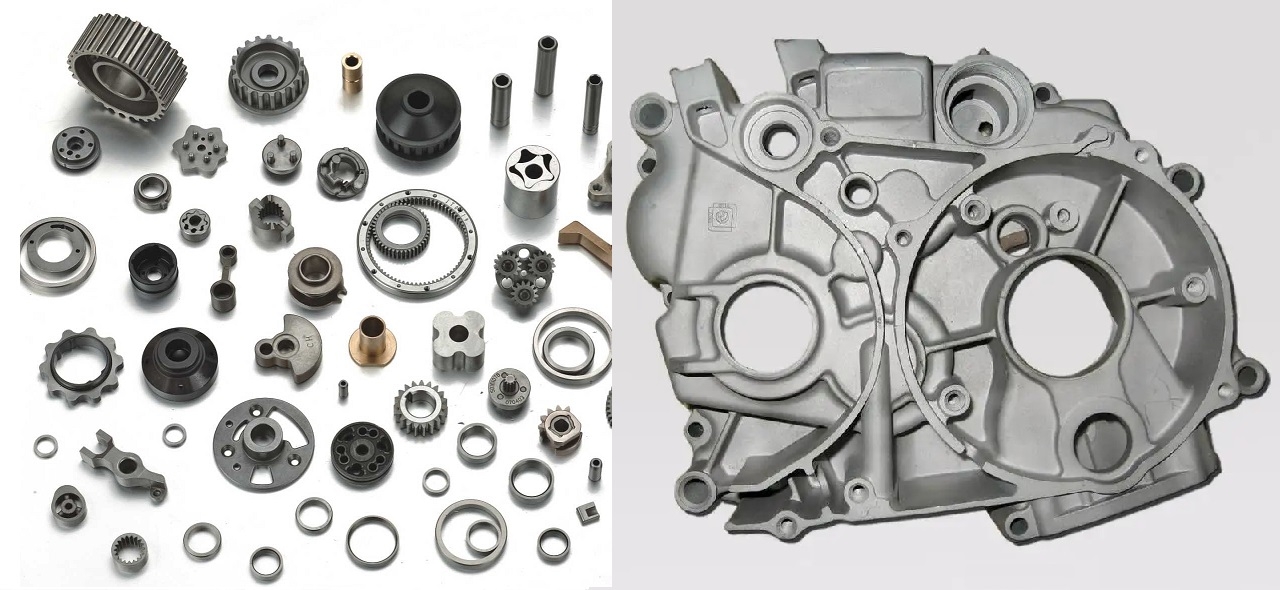

Khetho pakeng tsa metallurgy ea phofo le die casting hangata ke potso ea boholo ba karolo kapa litlhoko tsa thepa ho fapana le moruo.Lisebelisoa tse sebelisoang hangata ke li-alloys tsa aluminium, li-alloys tsa magnesium le li-alloys tsa zinki, le li-copper alloy die castings le tsona li sebelisoa ho isa bohōleng bo itseng.Ka lebaka la boemo bo phahameng ba ho qhibiliha ha ferroalloy le tšepe e sa hloekang, mokhoa oa phofo oa metallurgy o lokela ho sebelisoa.

Ha ho bapisoa le likarolo tsa metallurgy tsa setso, likarolo tsa ho etsa ente ea tšepe, litekanyo tsa likarolo tsa ho lahla li ka tšoana kapa tse kholoanyane.Ha ho hlokahala boitsebiso bo ka sehloohong, ho loketse ho sebelisa mokhoa oa metallurgy oa phofo.Mohlala, 1: matla a phahameng haholo, matla a ho tiea a li-alloys tse entsoeng ka tšepe tse entsoeng ka tšepe a phahame ka makhetlo a fetang a mararo ho feta a li-alloys tsa die-casting.2: Ts'ebetso e phahameng ea ho sesa le ts'ebetso e phahameng ea ho fokotsa likhohlano, e ka rarolloang ka li-alloys tse entsoeng ka tšepe le tse entsoeng ka koporo tse kentsoeng ka oli e tlotsang.3: Mocheso o phahameng oa ho sebetsa, o ka rarolloang ka li-alloys tse sintered tse entsoeng ka tšepe le tse entsoeng ka koporo.4: Ho hanyetsa kutu, alloy e entsoeng ka koporo e entsoeng ka koporo le tšepe e sa hloekang e ka finyella litlhoko

Pakeng tsa metallurgy ea phofo le die casting, zinki die castings e ka 'na ea e-ba sebaka sa lihlahisoa tsa metallurgy tse entsoeng ka tšepe ha mocheso oa ho sebetsa o sa phahametse 65 ° C mme matla a mahareng a hlokahala.Mekhoa ena e 'meli e ts'oana ka ho nepahala ha dimensional le tlhokahalo ea machining.Empa mabapi le litšenyehelo tsa lisebelisoa le machining, metallurgy ea phofo hangata e molemo ho feta.

Nako ea poso: Sep-26-2022