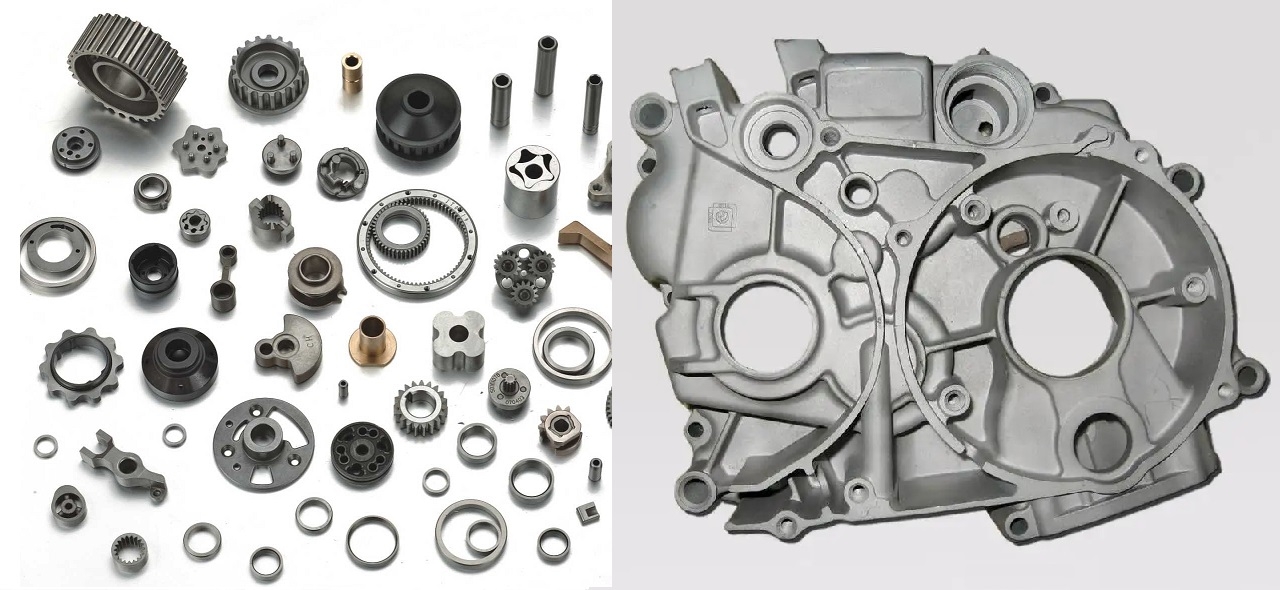

Ukukhetha phakathi kwe-powder metallurgy kanye ne-die casting kuvame ukuba umbuzo wosayizi wengxenye noma izidingo zezinto ezibonakalayo kunezomnotho.Izinto ezisetshenziswayo ezivame ukusetshenziswa kakhulu yi-aluminium alloys, ama-alloys e-magnesium nama-zinc alloys, kanye ne-copper alloy die castings nawo asetshenziswa ngezinga elilinganiselwe.Ngenxa yezinga eliphezulu lokuncibilika le-ferroalloy nensimbi engagqwali, inqubo ye-powder metallurgy kufanele isetshenziswe.

Uma kuqhathaniswa nezingxenye zensimbi zempuphu yendabuko, izingxenye zokubumba umjovo wensimbi, ubukhulu bezingxenye zokuphonsa zingafana noma zibe zikhudlwana.Lapho kudingeka impahla eyinhloko, kufaneleka kakhulu ukusebenzisa inqubo ye-powder metallurgy.Isibonelo, 1: amandla aphakeme kakhulu, amandla aqinile amanye ama-alloys asekelwe ku-iron aphakeme ngokuphindwe kathathu kunalawo ama-alloys e-die-casting.2: Ukumelana nokugqoka okuphezulu nokusebenza okuphezulu kokunciphisa ukungqubuzana, okungaxazululwa ngama-alloys asekelwe ensimbi kanye nethusi afakwe ngamafutha okugcoba.3: Izinga lokushisa eliphezulu lokusebenza, elingaxazululwa ngama-alloys asekelwe ensimbi kanye ne-copper-based.4: Ukumelana nokugqwala, ingxubevange esekelwe ethusi nensimbi engagqwali e-sintered ingahlangabezana nezidingo

Phakathi kwe-powder metallurgy kanye ne-die casting, i-zinc die castings ingase ibe indawo yemikhiqizo ye-iron-based metallurgy eyimpushana lapho izinga lokushisa lokusebenza lingekho ngaphezu kuka-65 °C futhi amandla aphakathi ayadingeka.Lezi zinqubo ezimbili ziyefana ngokuya ngokunemba kwe-dimensional kanye nesidingo somshini.Kodwa mayelana nezindleko zamathuluzi nemishini, i-powder metallurgy ngokuvamile inenzuzo kakhulu.

Isikhathi sokuthumela: Sep-26-2022